3d inspection

3D INSPECTION Services

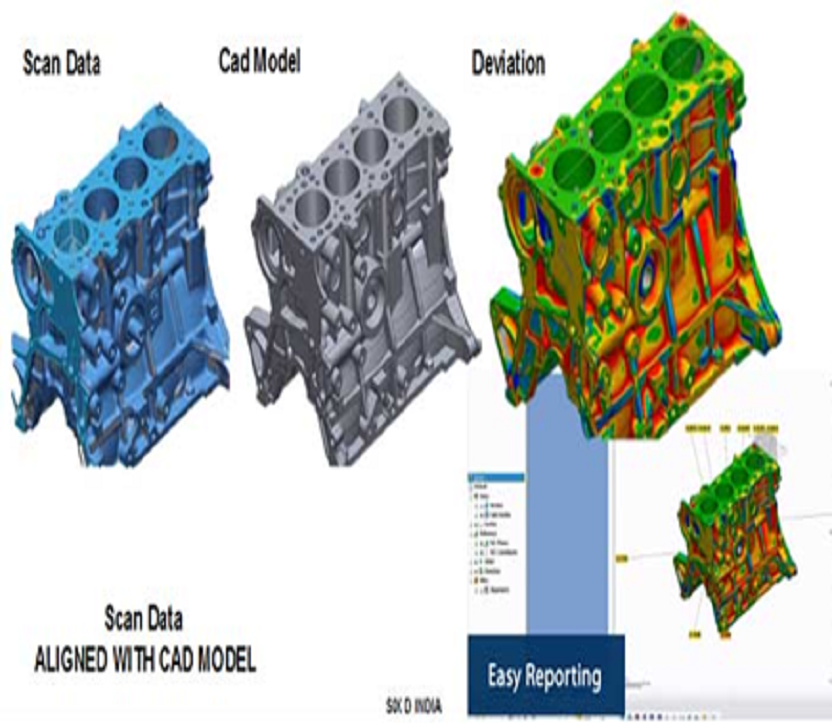

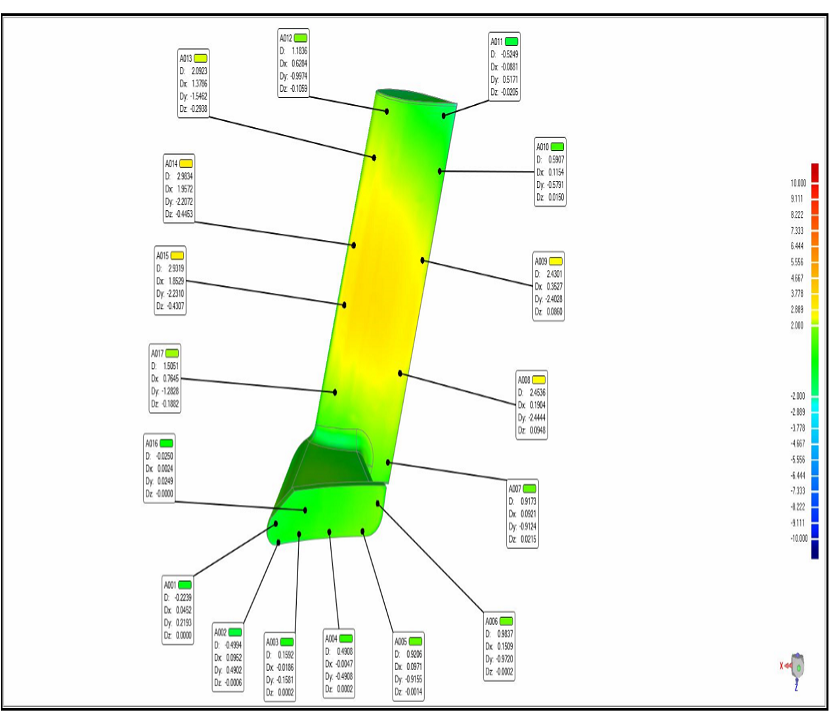

3D inspection services are of great help in comparing the CAD scanned model of an object to the original design intent. This helps establish the conformity of the manufacturing process and also any sets of CAD data can be compared while manufacturing process is underway to establish that all parts are within the spec.

3D Inspection Benefits

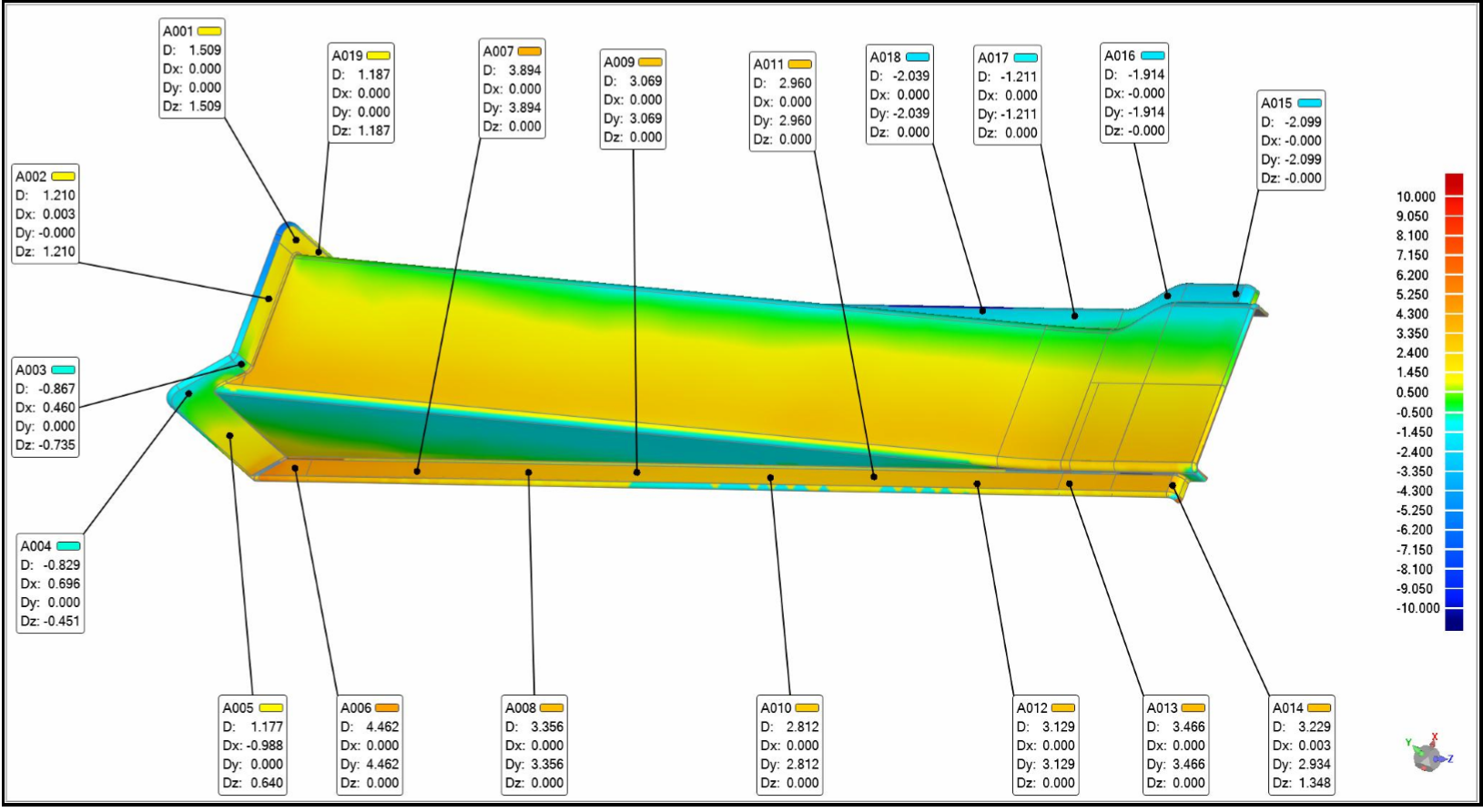

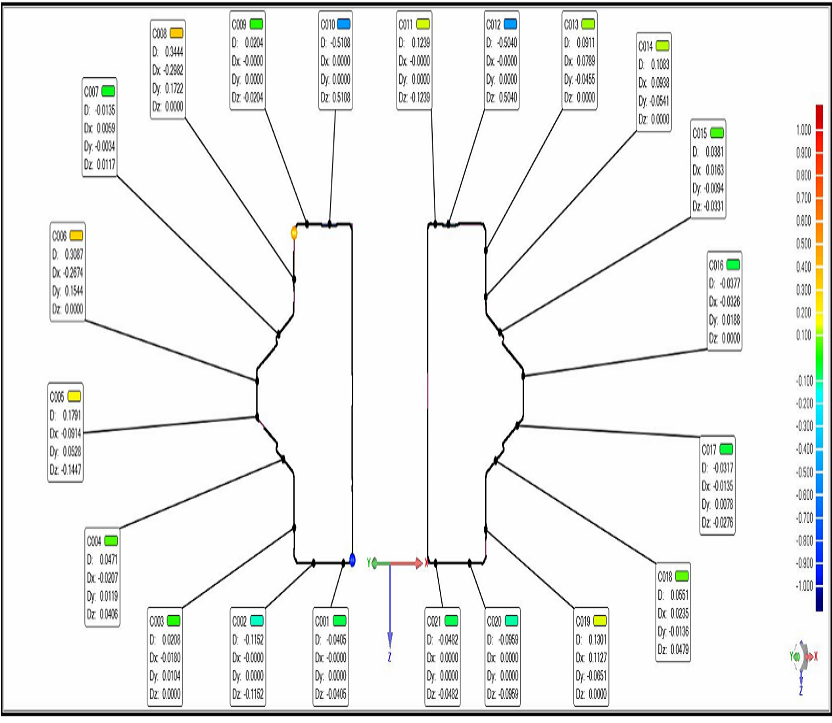

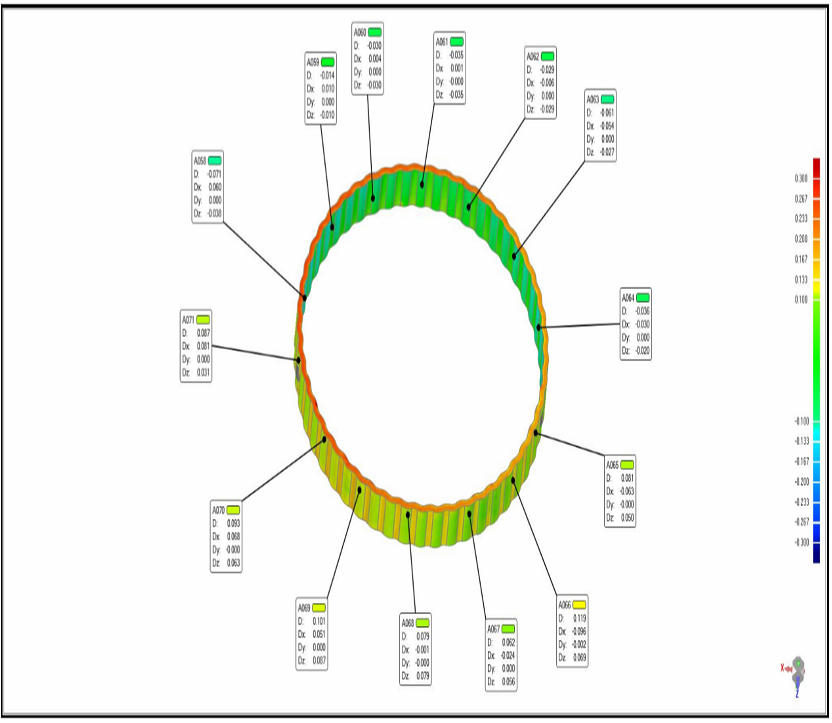

The 3D inspection is in the form of quality inspection using 3D laser scanning and employed at various stages of as-built physical objects to compare to their as-designed digital model. This process helps to uncover surface deviations such as warpage, tooling deterioration or other manufacturing defects and there by optimise the manufacturing process. 3D inspection is a leap jump from the traditional quality inspection technologies which involve use of coordinate measuring machine (CMM) and also require actual physical contact with the object being measured.

3D Inspection on the other hand do not require physical contact with the object and the resolution output is also very accurate.

Our expertise engineers with a wide variety of inspection technologies gives you the ability to:

- Quickly compare as-built to as-designed

- Spring Back Analysis

- Locate warpage

- Airfoil Analysis

- Find and fix manufacturing defects

- Measure cross-sections

- Identify areas in and out of tolerance